Did you know that a poorly chosen commercial roofing system can cost Florida businesses up to 40% more in energy bills and repairs over its lifetime?

Whether you’re constructing a new building or replacing an existing roof in Tampa, selecting the right commercial roofing system is a decision that impacts your business for decades. In fact, with Florida’s intense heat, frequent hurricanes, and high humidity, your choice becomes even more critical for protecting your investment.

Specifically, Tampa commercial buildings face unique challenges that demand careful consideration of roofing materials’ durability and weather resistance. From energy efficiency to hurricane protection, each factor plays a vital role in your roof’s performance and longevity.

This guide will walk you through the essential considerations for choosing a commercial roofing system that stands up to Tampa’s demanding climate while meeting your business needs and budget requirements.

Understand Your Building and Business Needs

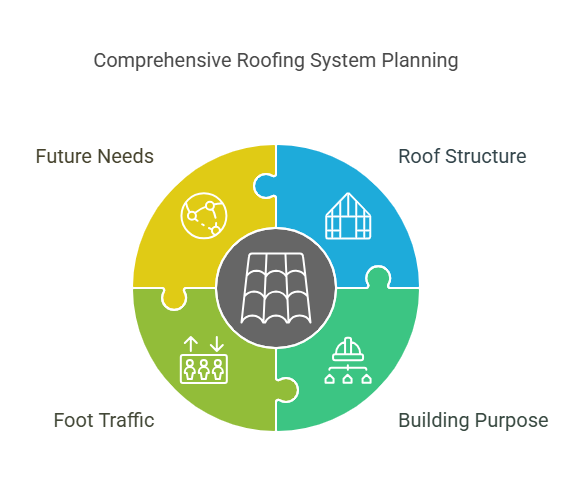

The foundation of choosing the right commercial roofing system begins with a thorough assessment of your building’s unique characteristics and operational requirements. Before exploring material options, understanding your structure’s fundamental needs ensures a roofing solution that performs optimally for years to come.

Assess your roof structure: flat, low-slope, or steep-slope

Commercial buildings typically feature one of three main roof structures, each with distinct advantages and applications. Identifying yours is the first critical step in the selection process.

Low-slope roofs (sometimes called “flat roofs”) have a pitch of 3:12 or less, meaning they rise 3 inches or less for every 12 inches of horizontal distance. Despite being called “flat,” these roofs always incorporate a slight slope for drainage purposes. They excel in large commercial settings like warehouses and shopping centers where expansive coverage is needed.

Steep-slope roofs feature a pitch greater than 3:12. These roofs allow water and snow to slide off naturally, making them less prone to water accumulation. They’re commonly used for office buildings, educational institutions, and structures where visual appeal matters alongside performance.

The choice between these structures depends on several factors:

- Building size and design requirements

- Local climate conditions and weather patterns

- Budget constraints (both initial and long-term)

- Energy efficiency goals

- Local building codes and regulations

Consider your building’s purpose and foot traffic

Your building’s function directly impacts what you need from your roof. A warehouse may require only basic protection from the elements, while restaurants and manufacturing facilities need systems that can accommodate exhaust vents and withstand chemical exposure.

Foot traffic is another crucial consideration. Commercial roofs often serve as platforms for:

- HVAC maintenance and repairs

- Equipment installations

- Routine inspections

- Other contractor activities

Regular rooftop foot traffic can significantly impact your roof’s integrity through:

- Mechanical stress from human and machinery movement

- Abrasion from repeated friction

- Potential for tears and punctures

- Insulation compaction reducing energy efficiency

- Accelerated deterioration of protective layers

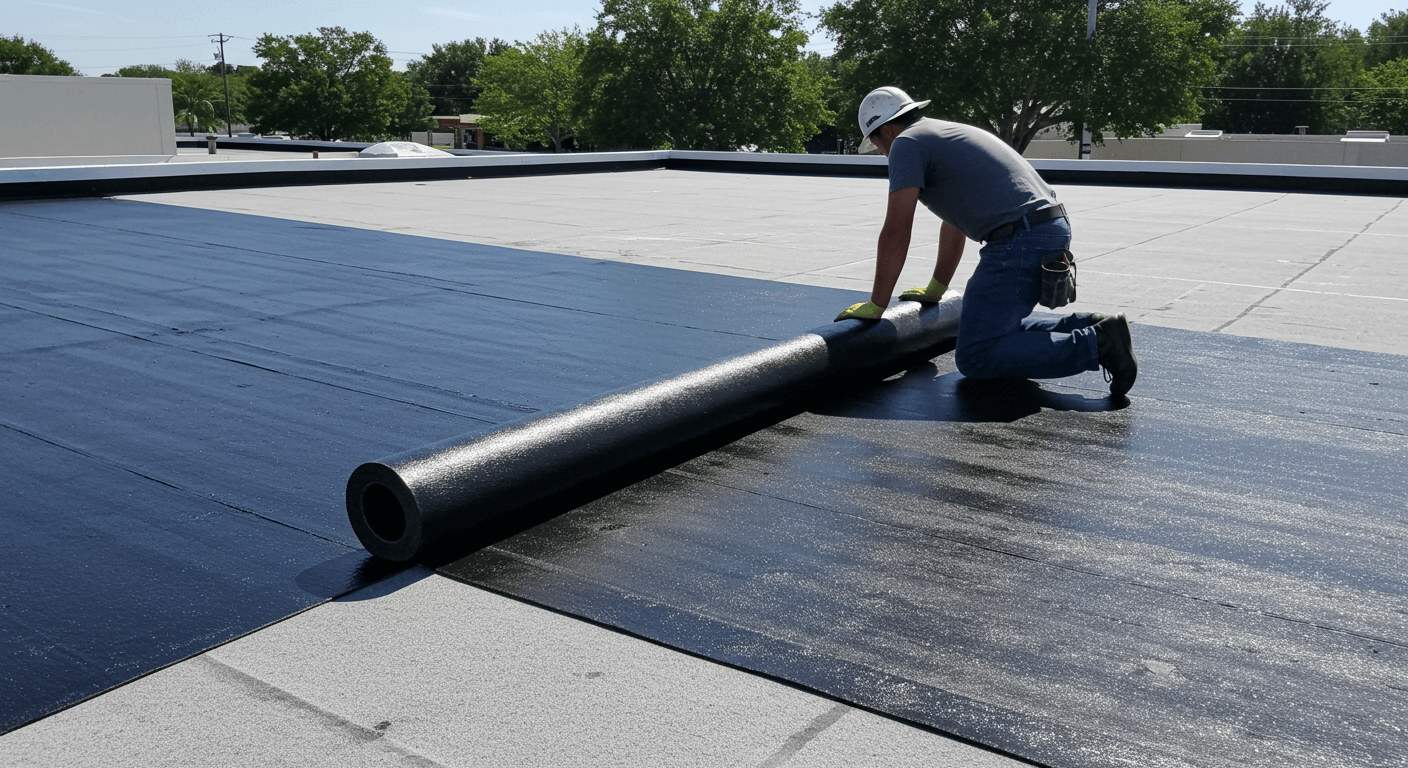

Buildings with high rooftop activity should consider more durable systems. For instance, modified bitumen roofing offers better resistance to foot traffic than thinner TPO membranes. Additionally, designated walkway systems can protect vulnerable areas by directing traffic away from sensitive parts of the roof.

Evaluate future expansion or equipment needs

Future-proofing your commercial roofing system requires anticipating tomorrow’s needs alongside today’s requirements.

Many commercial buildings house heavy equipment such as HVAC units, satellite dishes, and other mechanical systems on the roof. Consequently, your roofing must support these weight loads without compromising structural integrity. Low-slope roofs particularly excel at accommodating rooftop equipment, as they provide ample space for installation while keeping these systems hidden from view.

When planning for expansion, consider:

- Potential additional weight loads from new equipment

- The roof’s structural capacity to support changes

- Placement of current and future rooftop elements to avoid obstructing water flow

- Coordination between building systems (plumbing vents, electrical lines, HVAC)

- Access points for maintenance and equipment servicing

Built-up roofing systems offer excellent flexibility for buildings likely to undergo modifications, as their multiple layers provide additional durability and adaptability.

Remember that improper planning for equipment placement can create drainage issues leading to water pooling, which shortens roof lifespan. Therefore, a comprehensive layout that accounts for both current and future needs helps avoid costly problems down the road.

By thoroughly assessing these three key areas—roof structure, building purpose with foot traffic considerations, and future needs—you create a solid foundation for selecting the optimal commercial roofing system for your Tampa property.

Factor in Tampa’s Climate and Weather Risks

Tampa’s unique climate poses specific challenges for any commercial roofing system. After understanding your building’s structural requirements, it’s equally crucial to consider how Florida’s distinctive weather patterns will interact with your roofing materials over time.

Heat and UV exposure in Florida

The Sunshine State lives up to its name with Tampa experiencing approximately 246 sunny days annually—significantly more than the national average. This intense sun exposure creates two major concerns for commercial roofing:

First, continuous UV radiation breaks down roofing materials at the molecular level, causing premature aging, brittleness, and eventual failure. This degradation occurs much faster in Florida than in northern states, shortening the effective lifespan of many roofing systems.

Second, extreme heat creates thermal stress through constant expansion and contraction cycles. As temperatures fluctuate between scorching days and cooler nights, roofing materials repeatedly expand and contract, eventually leading to cracks, splits, and separation at seams.

To combat these issues, consider these heat-resistant options:

- Cool roofs with reflective surfaces that redirect heat away from your building

- TPO and PVC membranes that offer excellent UV resistance while reflecting sunlight

- Metal roofing with specialized reflective coatings to minimize heat absorption

Hurricane and wind resistance requirements

Unlike other regions, Tampa commercial buildings must withstand hurricane-force winds that can exceed 150 mph during severe storms. Moreover, Florida’s building codes are among the strictest nationwide regarding wind resistance.

Commercial roofing systems must feature:

- Proper edge securement to prevent “peeling” during high winds

- Enhanced attachment methods (mechanical fastening or heavier adhesives)

- Wind-rated materials certified for Florida’s coastal environment

- Strategic design that minimizes uplift potential

Metal roofing systems typically offer superior wind resistance compared to membrane options, especially when installed with concealed fasteners. However, properly installed modified bitumen systems also provide excellent hurricane protection due to their multi-layer construction and superior tensile strength.

Furthermore, many insurance providers offer premium discounts for buildings with certified wind-resistant roofing systems—an important consideration for overall operating costs.

Moisture and humidity considerations

Perhaps most challenging of all, Tampa’s combination of heavy rainfall (averaging 51 inches annually) and persistent humidity creates ideal conditions for moisture-related roofing problems. These conditions accelerate the growth of mold, mildew, and algae while promoting premature deterioration of certain roofing materials.

The moisture challenge extends beyond just rain protection. Your commercial roofing system must also:

- Maintain water-tightness during extended periods of standing water

- Resist algae and fungal growth that can degrade materials

- Provide proper drainage to prevent ponding water

- Include adequate ventilation to prevent condensation buildup

For these reasons, seamless membrane systems like TPO and PVC often outperform traditional built-up roofing in Tampa’s climate, as they eliminate vulnerable seams where water can penetrate. Additionally, these materials typically include algae-resistant properties essential for Florida’s humid conditions.

Ultimately, the ideal commercial roofing system for Tampa must balance all three climate considerations—heat resistance, wind durability, and moisture protection—while still meeting your building’s specific requirements and budget constraints. Working with contractors experienced in Tampa’s unique challenges ensures your roofing investment will stand up to Florida’s demanding climate for years to come.

Compare the Most Common Commercial Roofing Systems

Selecting among the various commercial roofing options requires understanding their distinct advantages and limitations. Each system offers unique benefits that may align perfectly with your Tampa building’s specific needs.

EPDM: Pros, cons, and best use cases

EPDM (Ethylene Propylene Diene Monomer) rubber roofing stands out as a cost-effective option for commercial buildings. This synthetic rubber material typically lasts around 20 years when properly installed and maintained. It excels in weather resistance, withstanding winds and hail up to 3 inches in diameter.

Key advantages include:

- Eco-friendly composition that’s 100% recyclable

- Fire-resistant properties that slow down fire progression

- Lower energy costs when paired with polyiso insulation

- Available in white (reflects UV rays) or traditional black

Essentially, EPDM works best for low-sloped roofs where budget is a primary concern. Nevertheless, potential drawbacks include its vulnerability to punctures, especially as it ages, and possible shrinkage of up to 4% over time, which can lead to “bridging” where the membrane stretches across areas instead of hugging the substrate.

TPO vs. PVC: Energy efficiency and durability

Both TPO (Thermoplastic Polyolefin) and PVC (Polyvinyl Chloride) offer exceptional energy efficiency through their highly reflective surfaces. Generally, these single-ply membranes help reduce cooling costs in Tampa’s hot climate by reflecting the sun’s heat away from buildings.

Although similar in appearance, their composition differs significantly. TPO consists of polypropylene and ethylene-propylene polymers without plasticizers, whereas PVC contains plasticizers for flexibility.

TPO typically costs less than PVC but offers greater tear strength (55 lbf compared to PVC’s 45 lbf). Alternatively, PVC provides superior chemical resistance—making it ideal for restaurants or buildings with chemical exposure—and stands as the most fire-resistant single-ply membrane available.

Both systems feature heat-welded seams that create stronger bonds than adhesive methods used with other systems.

Metal roofing: Longevity and cost trade-offs

Metal roofing systems deliver impressive longevity, typically lasting 40-60 years—significantly outlasting other commercial options. Initially more expensive than membrane systems, metal roofing provides substantial long-term savings through minimal maintenance requirements and energy efficiency.

Notably, reflective metal roofing can reduce air temperatures inside buildings by an average of 12 degrees, lowering cooling costs substantially. These systems withstand extreme weather conditions including high winds, heavy rain, and even fire—making them particularly valuable for Tampa’s hurricane-prone climate.

Popular options include:

- Galvanized steel with zinc coating for rust protection

- Galvalume steel with combined zinc and aluminum for superior corrosion resistance

- Standing seam designs with concealed fasteners for enhanced durability

Built-Up and Modified Bitumen: When layering matters

Built-Up Roofing (BUR) and Modified Bitumen systems excel when robust waterproofing is essential. BUR consists of alternating layers of bitumen (asphalt) and reinforcing fabrics, typically finished with gravel. This multi-layer approach creates redundant protection—if one layer fails, others continue providing coverage.

Modified bitumen combines the layered approach with polymer-enhanced flexibility, available in two primary types: SBS (providing elastic flexibility) and APP (offering improved UV resistance). These systems perform exceptionally well in areas with regular foot traffic due to their superior durability against mechanical stress.

Primarily, these layered systems shine for low-slope commercial roofs where ponding water presents concerns. Their dense structure provides excellent waterproofing and insulation properties, although they typically weigh more than single-ply alternatives.

Balance Budget with Long-Term Value

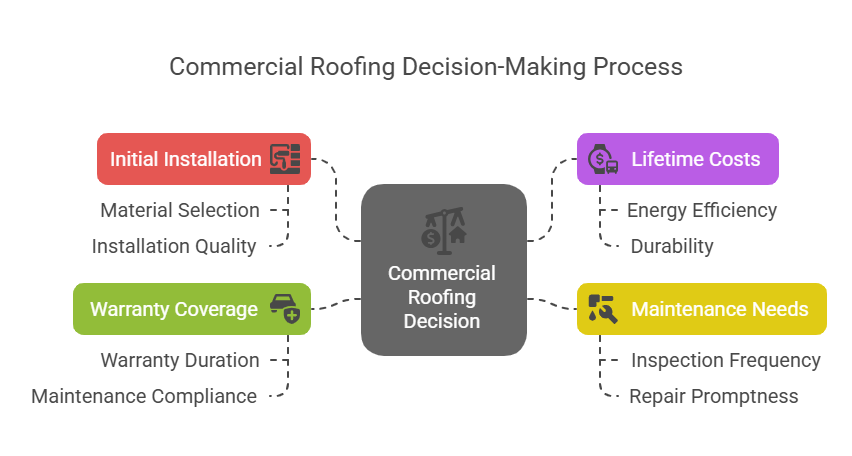

Making a cost-effective commercial roofing decision requires looking beyond the initial price tag. Smart Tampa business owners recognize that upfront savings often lead to higher expenses over the roof’s complete lifecycle.

Initial installation vs. lifetime cost

The true cost of a commercial roofing system extends far beyond installation day. Indeed, lifetime costs typically include ongoing maintenance, repairs, energy efficiency, and eventual replacement. While metal roofing systems have higher upfront expenses, they often deliver the lowest lifetime costs through exceptional durability and energy efficiency.

Consider these factors when evaluating total ownership costs:

- Energy efficiency impacts (reflective metal roofing can reduce indoor temperatures by up to 12 degrees)

- Durability in Tampa’s harsh climate

- Frequency of major repairs

- Potential insurance premium savings with hurricane-resistant options

As noted by roofing experts, “inexplicable rises in energy costs are one of the telltale signs it’s time to replace a commercial roof”. Accordingly, a higher initial investment in quality materials and expert installation helps minimize unexpected expenses throughout the roof’s lifespan.

Maintenance needs and repair frequency

Regular maintenance dramatically extends commercial roof lifespan—anywhere from 30% to 100% according to the National Roofing Contractors Association. Preventative maintenance typically costs just 5-9 cents per square foot yet prevents problems that could otherwise cost thousands to repair.

Most commercial roofing experts recommend:

- Semi-annual inspections (spring and fall)

- Additional inspections after severe weather events

- Prompt repair of minor issues before they escalate

Without proper maintenance, a commercial roof that could last 30+ years might require replacement in just 15-20 years. Subsequently, skipped maintenance often means replacing rather than restoring—costing approximately $10 per square foot versus $5 per square foot for restoration.

Warranty coverage and expected lifespan

Commercial roofing warranties vary significantly in coverage and duration:

- Standard warranties: 10-25 years for asphaltic membranes

- Extended options: Up to 35 years for qualifying systems

- NDL (No Dollar Limit) warranties: Cover full replacement costs regardless of price increases

Primarily, warranty validity depends on following manufacturer maintenance requirements. Most warranties require semi-annual professional inspections and prompt repairs. Obviously, documented maintenance history becomes crucial when filing warranty claims.

Commercial roofing lifespans vary by material type:

- EPDM: 22-35 years

- TPO: 10-30 years

- Metal: 30-45+ years

- PVC: 20-30 years

- Built-Up Roofing: 20-40 years

Work with a Qualified Tampa Roofing Contractor

Finding the right contractor completes your journey to a successful commercial roofing system. Your carefully selected materials and designs mean little unless installed by skilled professionals familiar with Tampa’s unique challenges.

Check for local licensing and insurance

Primarily, verify that any commercial roofing contractor holds proper licensing through Florida’s regulatory bodies. Licensed contractors demonstrate minimum competency standards and commitment to professional standards. Ask for their license number which can be verified through the state’s licensing board.

Comprehensive insurance coverage protects both your property and your business from liability. Request proof of both general liability insurance (which covers property damage) and workers’ compensation (which protects against worker injuries). Insurance experts recommend contractors carry policies between $2-5 million in coverage for commercial projects.

Ask about experience with your chosen system

Simply having years in business isn’t sufficient—contractors need specific experience with your selected roofing system. Ask potential contractors about:

Their track record with your chosen material, including completed projects you can visit

Their installation training and manufacturer certifications

Their approach to common challenges with your system in Tampa’s climate

Many manufacturers provide specialized training for their commercial roofing systems, and contractors who have invested in this training typically deliver superior results. Certifications often allow contractors to offer enhanced warranty options unavailable through non-certified installers.

Get a detailed quote and timeline

Comprehensive quotes protect you from unexpected costs and project delays. Certainly request:

- Material specifications with manufacturer information

- Labor costs broken down by phase

- Timeline with major milestones and completion date

- Permit acquisition procedures and costs

- Detailed warranty information for both materials and workmanship

Since commercial roofing projects are substantial investments, obtain multiple quotes from local contractors. A typical 3,000 square foot commercial roof takes approximately four days to install, with larger projects requiring proportionally more time.

Clear communication systems matter immensely in commercial projects. Choose contractors who utilize multiple communication channels and respond promptly to inquiries about your commercial roofing system.

Final Thoughts on Selecting the Ideal Commercial Roofing System for Tampa

Selecting the right commercial roofing system stands as a critical decision for Tampa business owners. Each building presents unique challenges, requiring careful evaluation of structural needs, climate demands, and budget constraints before making this significant investment.

Success lies in balancing multiple factors – from your building’s specific requirements through Tampa’s harsh weather conditions to long-term cost considerations. Rather than focusing solely on initial expenses, smart business owners evaluate total lifecycle costs, including maintenance, energy efficiency, and potential repair needs.

Quality materials paired with expert installation create roofing systems that protect Tampa businesses for decades. Professional contractors familiar with local conditions ensure proper installation while helping navigate material choices and maintenance requirements. Through careful planning and informed decisions, your commercial roof will shield your business investment against Florida’s demanding climate while providing reliable, long-term protection.